Steel ingot

Steel ingot (Billet)

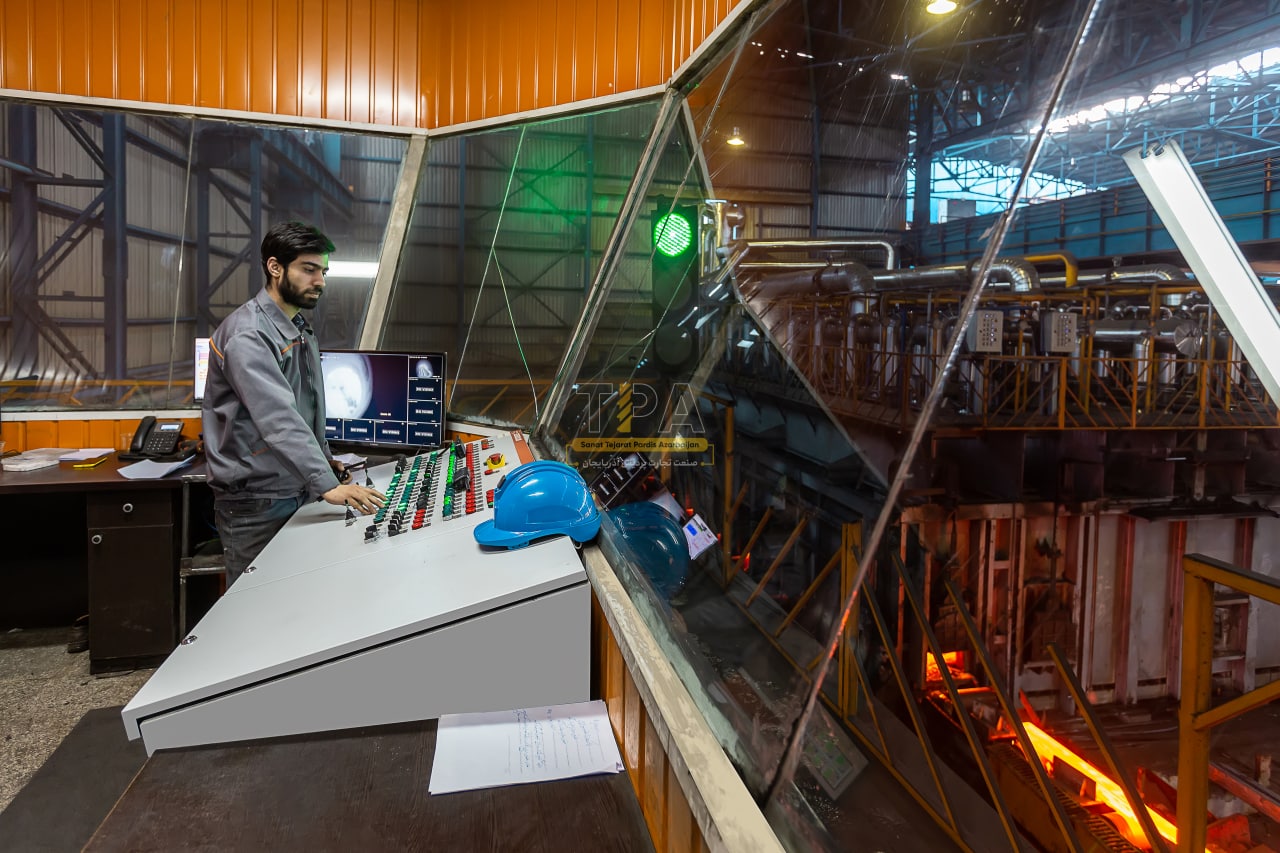

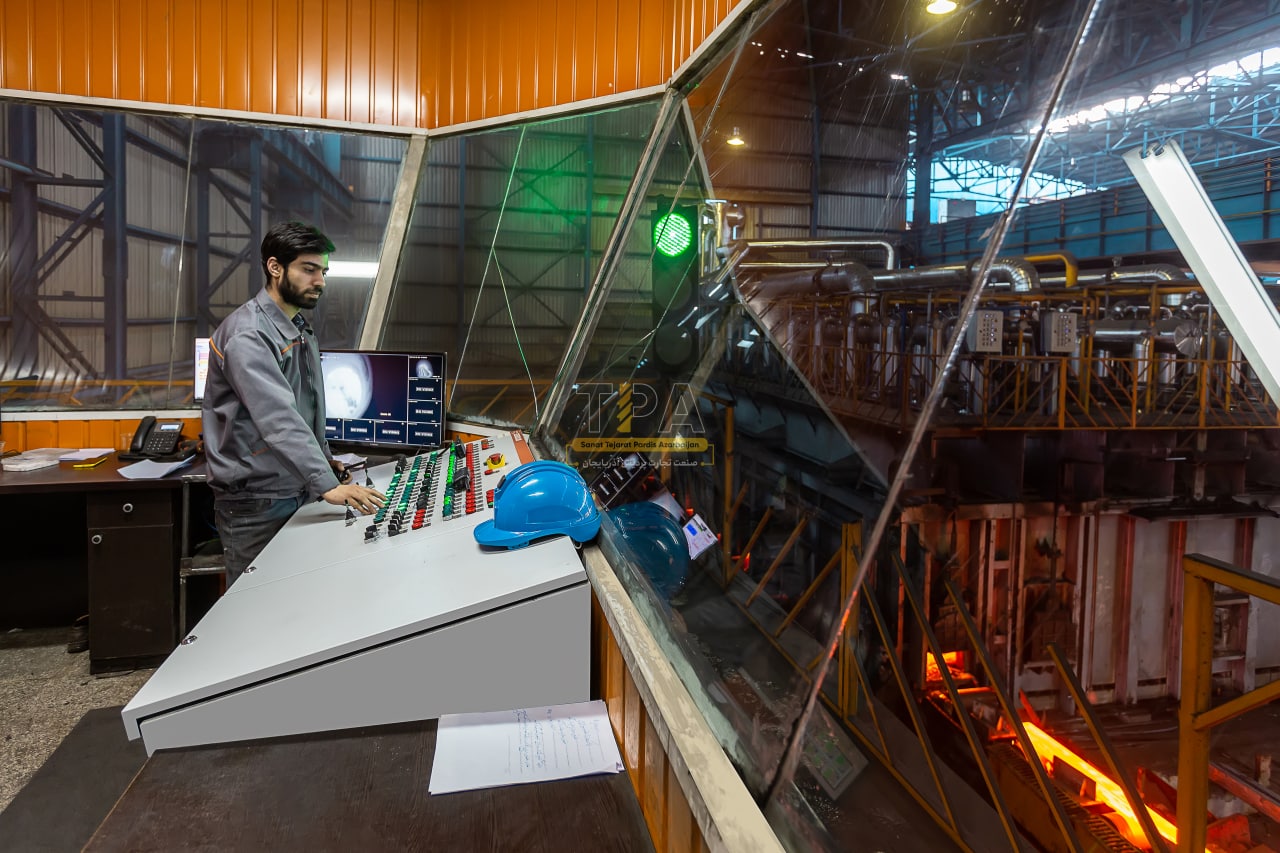

Sanat Tejarat Pardis Azerbaijan Factory has been operating as one of the main factories in the country in the field of steel products production, including steel ingots. Steel ingot is one of the most important products that must be produced with diligence and application of modern science; Because this material is considered the main composition and builder of any other steel section such as rebar. At Sanat Tejarat Pardis Azerbaijan factory, we always try to help the customer in choosing the best type of product by improving the quality of raw materials and using modern methods. In the following, you will get acquainted with the types of steel ingots produced in this factory and you will get information about the unique characteristics of each sample and the standards used in their production.

Our Steel Ingot Products

3SP/4SP/5SP

Steel ingot; The main product of the Sanat Tejarat Pardis Azerbaijan

Sanat Tejarat Pardis Azerbaijan factory produces steel ingots in addition to rebar production. Steel ingot is a certain amount of metal that is formed into different molds in the casting process and is used in the architectural industry and the production of other steel sections according to the shape. This steel product is made in different forms such as slab, billet and bloom. The length of these sections is generally less than two meters and it is inspected and controlled by using the world’s leading standards such as 20300-1398 INSO (National Standard of Iran), 2005-10080 EN (European Standard) and 2005-380 GOST (Russian Standard) to Reach customers with the highest quality and resistance.

Production of steel billets in accordance with the national standard of Iran

The steel billet made in this factory using the INSO 20300-1398 national standard includes grades R1, R2, R3, R4-A, R4-B, R5, R6, R7 and, R8. Each of these grades has a certain amount of raw materials due to the need for a certain amount of resistance. The raw materials of Sanat Tejarat Pardis Azerbaijan factory steel billets are carbon, silicon, manganese, phosphorus, sulfur and other organic materials, each of which is used in a certain amount in various grades. Only grades R3, R5, R7 and, R8 are made with nitrogen. The amount of sulfur and phosphorus in the steel billet grades made according to the national standard is the same, and it is the changes in the amount of carbon, silicon and manganese, which determines the strength and properties of each grade.

Production of steel billet grades according to Russian standards

Percentage are applied in the steel billet produced in accordance with the Russian standard GOST380-2008. Russian standard steel billet grades include ST 3SP, ST 4SP, and, ST 5SP, and the mineral materials such as silicon, sulfur, and phosphorous are the same; While the amount of carbon and manganese used are different. The changes in minerals in this type of steel billet are such that as the grade number increases, the amount of carbon and manganese used in the parts increases.

Steel billets produced according to European standards

The grades related to each standard are also different from each other, and this is the reason why we, as one of the top steel billet production factories in the country, have the utmost precision in separating these products. The European standard suggests that steel billets be made according to the S235JR (ST 37), S275JR (ST 44) and, S355JR (ST 52) grades, and in our production unit, we produce this sample of steel billets with equal amounts of compounds such as manganese, phosphorus and, sulfur and varying amounts of carbon and silicon. Two samples of steel billets S235JR (ST 37) and, S275JR (ST 44) do not contain silicon, and sample S355JR (ST 52) has the highest amount of manganese among other samples.

Frequently Asked Questions

The steel billets produced in Sanat Tejarat Pardis Azerbaijan factory are of different types and are produced according to the national standards of Iran, Europe, and Russia.

The best steel billets of Sanat Tejarat Pardis Azerbaijan factory may differ according to the needs and conditions of your project; Therefore, it is suggested to contact our experts for consulting.

For information about the types and details of steel ingots produced in our steel factory, considering the elegance of the design and the minor differences of each sample, please contact one of our representatives.